Material - Plywood

Plywood probably isn't the first material most people would associate with the stylish designs of the 20s and 30s, but it played an important role as a material in the Art Deco and Streamline Moderne design, both in furniture and interior design.

Plywood, Paimio Chair, Alvar Aalto, 1932, reddit;

While the basics of plywood creation date to antiquity, important changes to the way it was made allowed this material to become quite relevant to the period. "Plywood... was one of a raft of new, 'modern' building materials introduced and experimented with from the 1920s, but especially in the 1930s and 1940s. Within this history it occupies a unique position, as it was both a modern and a conventional material: 'high-tech', standardized and industrial; but with strong links to more traditional timber construction." (Christopher Wilk, Plywood - A Material Story, 2017, p. 105)

Plywood has two advantages over solid wood. First, it is stronger, particularly when each thin piece of wood (called a 'ply') is placed with the direction of the wood grain at a right angle to the one next to it and glued. (This is called cross-graining.) Second, the resulting composite board does not expand or contract with temperature nearly as much as solid wood.

Plywood can have other advantages over wood. It can be made with interior plies made of less expensive woods since only the outer ply while is seen, making it less expensive than if a solid piece of the expensive wood alone were used. This is what is most people think of as a veneer. Another advange is that such plywoods made with rarer wood outer veneer help preserve to preserve such exotic hardwoods by being able to make more boards from a single tree. "A single cubic metre of timber can produce 900 square metres of veneer. There is hardly any waste." ("Why is Real Wood Veneer Used on High End Furniture?", Olsen + Baker website, gathered 4/14/24) From a cost perspective, this was particularly useful in locations where desirable hardwoods had been over-harvested making and expensive due to costs of transport.

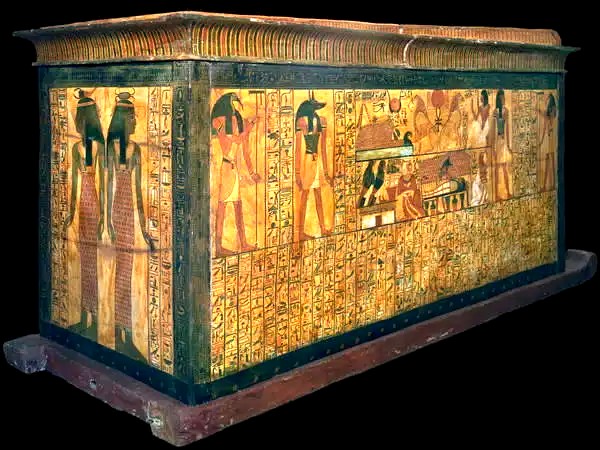

Outer Coffin of Khonsu Employing Plywood, ca. 1200 BCE, Egypt-Museum

Furniture made of veneered plywood dates back to ancient Greece and Egypt. Egyptian craftsmen used thin strips of dark ebony to decorate a cedar casket found in Tutankhamun's tomb. While most of the ancient examples were glued so that the direction of the grain of each ply had the grain in the same direction of the grain below it, there are examples from Egypt which have the plies glued crossgrained. Some of them that date to around 2700 BCE.

Near the beginning of the common era, (77 CE), Pliny the elder wrote that covering less expensive woods with more expensive ones was "bestowing upon the more common woods a bark of higher price. In order to make a single tree sell many times over, laminæ of veneer have been devised". (Pliny the Elder, The Natural History, Translated by John Bostock, gathered 3-10-25)

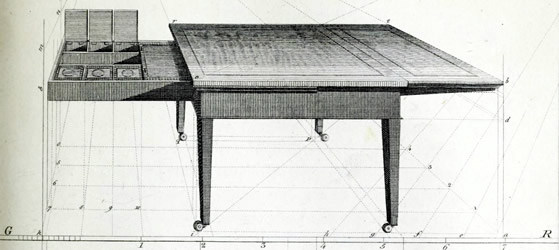

While such examples may seem to suggest plywood was used in antiquity, extant examples suggest it was uncommon. (It is alos possible that the more common examples just didn't survive.) In 1793, plywood was being used for a different reason. Thomas Sheraton explained in his book on building furniture that he made table tops for some of his 'universal tables' where "the pannels are sometimes glued up in three thicknesses, the middle piece being laid with the grain across, and the other two lengthways of the pannel, to prevent its warping." (Sheraton, The cabinet-maker and upholsterer's drawing-book: in three parts, 1793, p. 357) In the first half of the 19th century, furniture makers all over the world continued to find ways to use plywood in their furniture including in Belgium, Prussia,

Denmark and the US. (Wilk, p. 21)

Sheraton's Universal Table, The cabinet-maker and upholsters drawing-book in three parts, p. 363 (1793)

Veneered plywood furniture regained some popularity in the middle of the 18th century. Three ply cross-grained wood began to be used to create chair backs with latticed patterns cut out from the plywood boards using fret saws around this time. "The protection against splitting that plywood gave meant that ever finer frets could be cut, compared with those cut from a solid board or made from solid pieces joined together." (Wilk,p. 18-9)

Another use was patented in 1856 by John Henry Belter for 'pressed' plywood. His process glued 1/16th inch cross-grained plies under pressure which allowed them to be bent into a curved shape. The plies were pressed into shape using heated molds which kept the glue liquid as each ply was added. In this way, a curved chair back and seat could be made from a single piece of plywood. This practice was later further refined as we shall see, being used during the 1930s to make exotic-looking seats like the one at the top of the page and the one at right.

As machinery was developed to make the cutting of veneers faster and more efficient in the 19th century, cost were dramatically reduced. Several different methods for cutting veneers meant that different quality veneers could be more consistently produced. This allowed lower quality veneers to be sold to furniture companies who could then put more exotic veneers on less expensive furniture.

Molded and Laminated Plywood Chair, Marcel Breuer, Brooklyn Museum. ca. 1935-6, wikimedia

Unfortunately, this led to expensive veneers being glued to pine substructures which was were advertised as being made from the more expensive wood. Such practices cause the word, 'veneer' to suggest poor quality furniture to the buying public. (This echoed Pliny's 1800 year old criticism of the practice.)

This led to a crisis within the furniture industry regarding the use of plywood which resulted in a need for greater transparency as well as an effort to educate the public. A variety of articles were written around the turn of the century pointing out tje widespread use of plywood in the furniture industry, highlighting the benefits of using plywood. Wilk cites several arguments which were presented by a variety of sources from the period:

'Modern furniture is not solid, but is built up ... from five to seven distinct layers of wood, each layer running crosswise in grain to its neighbour.' Second, it was suggested that veneered furniture (explicitly identified as made of ply construction) was not cheap but 'the finest and most expensive furniture made today ... far more beautiful than solid wood' and 'arranged cross-grained'. ...Finally, the most convincing and consistent argument made in favour of plywood was that, unlike solid wood, it did not shrink (or by no more than 1%), split, swell or check (naturally separate along the grain), and that it was, in recommended applications, undeniably stronger than solid wood. (Wilk, p. 63)

Veneered wood furniture continued to be made, likely glued to plywood in some cases, whether the public recognized it or not.

Plywood underwent dramatic study and improvement with the advent of war. Its production was encouraged during World War I as the need for airplanes to fight the ware increased.

Plywood Toughness Test, Forest Products Laboratory, 1919, Nara Get Arch"Government sponsored research on plywood was first undertaken in the US and with a sense of urgency in June 1917, owing to demands that the US War Department produce 22,000 aeroplanes within 13 months." (Wilk, p. 75) The research was conducted by the US Forest Service's Forest Products Laboratory (FPL) in Madison, Wisconsin. A variety of tests were performed looking at various structural aspects of plywood: tension, splitting, warping, shrinkage, strength, stiffness and its ability to bend.

Other aspects of Because the planes would be flown in a variety of conditions, research was also devoted to the production of waterproof glues to bond the plies together. The resulting glue relied on albumin from animal blood. Research into molding techniques for plywood led to the creation of a molded plywood shell which was so strong that it didn't require an internal support structure. Being governmentally funded, all of this research was published after the war which allowed companies to began manufacturing better plywood in the interwar Art Deco era.

Veneer was often used to create interesting geometric designs in the wood using the natural grain in exotic hardwoods. This doesn't mean that all veneered furniture was plywood. Like the 19th century application of veneer to pine, exotic hardwards were sometimes applied to more common woods like oak. Unlike the late 19th century, decorative veneering

Sideboard, Waterfall Front with Bookmatched Veneer and Inlay, Carved Wood Appliques,

Brass Pulls, Etched Mirror, 1940s, Everything But the House

celebrated the fact that veneer was being used rather than trying to hide it.

After the Depression began in America, inexpensive wood furniture began being manufactured using a plywood base with a veneer of more expensive woods. Bookmatching veneer and exotic wood inlays were frequently employed to make the furniture more visually appealing. Carpathian elm and golden padouk were often glued atop the plywood. It was then often treated with blonde veneer or walnut polish. The distinctive quarter-round 'waterfall edges' found on this furniture were molded.

While synthetic glues existed when this furniture was created, furniture veneers were much more likely to be bonded with less expensive hide glue. Hide glue is made by boiling the connective tissue of animals. It does not hold as well as the synthetic glues which actually gave it an advantage. Although plywood doesn't expand as much as solid woods, it does still shift. The weaker hold provided by hide glue allowed some flexibility when this occured. Yet hide glue is also inferior to sythentic glue even on this type of furniture because it cannot withstand repeated or long-term exposure to moisture without weakening or breaking down. This is why you often find the veneer coming loose on Art Deco furniture.

Waterfall Furniture Veneers, from left - Plywood, Waterfall Armoire and Secretary Front Closed, Wallnut Marquetry, Satinwood Inlays, Mirrors, Bakelite and Metal Hardware, Cedar Lined, 1941, Ebay; Waterfall Buffet Table, Marquetry and Bakelite Handles, Wikipedia; Waterfall Nightstand, Walnut, Mahogany and Zebrawood Veneer with Starburst Marquetry, Restored Brass and Bakelite Hardwre, 1930s, Harp Gallery

Waterfall Furniture Veneers, from left - Plywood, Waterfall Armoire and Secretary Front Closed, Wallnut Marquetry, Satinwood Inlays, Mirrors, Bakelite and Metal Hardware, Cedar Lined, 1941, Ebay; Waterfall Buffet Table, Marquetry and Bakelite Handles, Wikipedia; Waterfall Nightstand, Walnut, Mahogany and Zebrawood Veneer with Starburst Marquetry, Restored Brass and Bakelite Hardwre, 1930s, Harp Gallery

Plywood was also used as wall paneling during the 1930s, being used on the walls of offices, ocean liners, government buildings and in private homes, including exclusive dwellings like Eltham Palace in London. (Seen below.) Plywood's reduced expansion and shrinkage when exposed to varying temperatures made it more effective than solid wood paneling. Other advantages were similar to those for furniture: It could be faced with a variety of interesting grained woods, it was easy to install and less expensive than solid wood panels. Plywood also came in standard sizes, making it easy for designers to plan for and implement.

Plywood was publicized throught its use in a variety of structures at the 1933 Chicago World's Fair, exposing the general public to the material as a viable wall covering. It was put to even more dramatic use as an interior wall covering at the 1939 New York World's fair in the Finnish exhibit. (Seen below.) The exhibit featured a tall, wavering and inclining wall built of large birch-fronted curved plywood panels, highlighting the material's flexibility. Decorative rectangular strips of native Finnish woods were then attached to the plywood surface with spaces for photographs.

Plywood Paneling (aka Veneers), from left - Finnish Pavillion by Alvar and Aino Aalto, 1939; Eltham Palace Entrance Room, 1936, Weil-Worgelt Study, 1930

Plywood Paneling (aka Veneers), from left - Finnish Pavillion by Alvar and Aino Aalto, 1939; Eltham Palace Entrance Room, 1936, Weil-Worgelt Study, 1930

By the mid 1930s, synthetic glues were being used by manufacturers to create water resistant and even waterproof plywood sheets. These plywoods could be used as a building material rather than just for decorative interior paneling. A "House of Plywood" was displayed at the 1939 New York World's Fair highlighting the many possible ways it could be used.

[T]he Plywood House featured the full range of Douglas fir plywood products deployed in what to contemporaries was the most up-to-date moderne style: waterproof exterior plywood ...on top of an intermediary layer of strengthening Plyscord sheathing, a roof of those same materials, interior walls of slightly pigmented Plywall... Plypanel interior cabinet work, a kitchen and a bathroom finished in (experimental) 'enamelled fabric' over plywood, subfloors of water-resistant Plyscord. and a concrete foundation poured into Plyform forms (Wick, p. 119)

In this way, Plywood had thus made the journey from a despised, inferior product in the late 1800s to a potential all-purpose material suitable to every aspect of construction in the 1930s.

Plywood House, New York World's Fair, 1939

Plywood House, New York World's Fair, 1939

Resources Not Mentioned Above:

Marjan Groot, "Materials, Artistic Craftwork and Modernist Furniture Design: The Kuyken Firm in the Netherlands and Belgium 1918 - 1940, The Journal of Modern Craft, Vol 13, 2020, Issue 3

Plywood - The Design Material, Toktokjp,e/ca. gathered 4/14/24

"Wood Veneer Terminology", wiseWood veneer, gathered 4/14/24

"King Tutankhamun's Plywood Legacy!", Polmac (UK) Limited, gathered 4/14/24

"Moderne Home: Veneer Furniture", freepedia.co.uk, gathered 4/14/24

Carl A. Eckelman, "Brief Survey of Wood Adhesives, Purdue University Extension Service Bulletin FNR 154

"Plywood", Wikipedia.com, gathered 4/14/24

"Urea formaldehyde", Plastiquarian.com, gathered 4/14/24

"IG Farben", Wikipedia.com, gathered 4/14/24

"Using CA glue to repair veneer", Fine Woodworking website, gathered 4/14/24

Jennifer Y. Chuong, "The Nature of American Veneer Furniture, circa 1790-1810", Journal 18 website, gathered 5-10-25

Discussion on Refinishing Waterfall Furniture, reddit, gathered 3-11-25

"Waterfall Furniture" Wikipedia, gathered 3-11-25

Plywood Furniture Examples, from left - Bar Cart, Plywood with Metal Handles and Wheels, 1930s, Chairish; Tea Cart, Brich FrontPlywood, Alvar Aalto for Horgenglarus, Early 1930s, Pamono; Bent Wood Chair, Gerald Summers, 1933-4, Kirkland Museum;; Molded Plywood Chairs, Plywood & Chromed Metal, c. 1927, 1st Dibs; Plywood, Bentwood Pedestal Desk, Paul Goldman for Plymold, 1930s, San Diego Online Estate Sales;

Plywood Furniture Examples, from left - Bar Cart, Plywood with Metal Handles and Wheels, 1930s, Chairish; Tea Cart, Brich FrontPlywood, Alvar Aalto for Horgenglarus, Early 1930s, Pamono; Bent Wood Chair, Gerald Summers, 1933-4, Kirkland Museum;; Molded Plywood Chairs, Plywood & Chromed Metal, c. 1927, 1st Dibs; Plywood, Bentwood Pedestal Desk, Paul Goldman for Plymold, 1930s, San Diego Online Estate Sales;