Material - Vitriolite, Carrera and Other Pigmented Structural Glasses

A material which was popularized during the Art Deco and Streamline Moderne eras was pigmented structural glass (PSG). It was originally created in 1900 by Marrietta Manufacturing Company in Indianapolis,

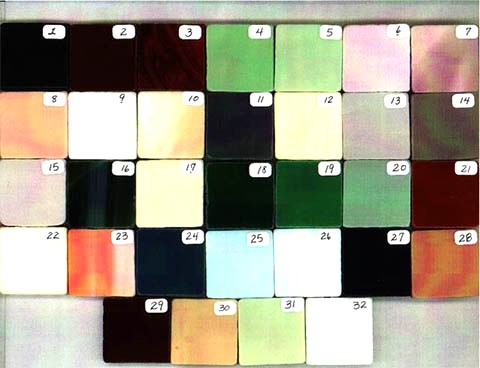

Vitrolite and Other PSG, Color Chips, Vitrolite Specialist

Indiana who marketed as 'Sani Onyx' or 'Sani Rox' with the description calling it a 'vitreous marble'. In 1906, glassmaker Pittsburgh Plate Glass Company developed a competing product which it named Carrara. In 1908, Meyercord-Carter Company began manufacturing Vitrolite, ultimately renaming the company Vitrolite in 1910. Vitriolite was eventually purchased by Libby Owens Ford in 1935. Other brands of PSG were marketed by competitors including Argentine, Glastone, Marbrunite, Nuralite, and Opalite. Yet Vitrolite and Carrara dominated the market during the heyday of this material.

When manufactured, PSG was heated to 3000 degrees F and then annealed (very gradually cooled) for several days, creating a very strong glass with a compressive strength nearly 40 percent greater than marble. The finished side was flame polished making it highly reflective. Tiles were among the most popular finished products, likely because of the compressive strength of PSG combined with its reflective marble appearance. It was also cheaper than marble which likely also played a role in the decision to market it as an alternative.

The first colors of PSG made available by Marietta Manufacturing were beige, black and white and were marketed as lining material for refrigerators. However, industrial customers found other interior design uses for the material including tabletops, countertops and dados (decorative, non-wood lower wall panels similar to wainscot).

Vitrolite and Other PSG, Black and Green Bathroom Tiles, UK, c. 1930s-40s

Philadelphia Plate Glass and the Vitrolite company introduced a variety of new colors after 1930 as interest in using the material for store fronts, signs, and tiling increased. (The image at left provides an example of some of the colors which were eventually available.) New Vitrolite colors appeared in 1936 after the acquisition by Libby Owens, including "agates" which simulated real marble and matte finishes. LOF also made every color available in full-sized sheets while Pennsylvania Plate only offered some colors that way.

Color variations aside, the biggest difference between Vitrolite and Carrara was that Vitrolite had fine grooves on the back to allow better bonding using mastic while Carrara was smooth, requiring the mating surface to be roughened for bonding. "Carrara and Vitrolite were essentially identical in [external] appearance and application so the story of their rivalry is more than anything else, about marketing." (Decopix)

Pigmented structural glass does not craze, swell, or warp, is very burn and stain resistant, and maintains its color. Because it is a glass, it is impervious to moisture and doesn't absorb bacteria or fungi. Although it is stronger than marble, as a type of glass it could be scratched and break.

Vitrolite and Carrara were found in a variety of Streamline modern interiors and products. "Vitrolite structural glass was in many ways the perfect art deco surface; sleek, hard, and lustrous as ice in a sunbeam." (Victorian Secrets) Curiously, although it is said that more Carrara was sold than Vitrolite, Carrara is only rarely mentioned when noting the type of PSG found in antique furniture, tiling or facades. Even the Etched Carrara Mural found in the Cloud room of the

Parts 3D Printed from Vitrolite, 3D Solutions Store. Note that these parts lack the glossy finish

which manufacturers in the 30s, 40s and 50s created by flame polishing.

Chrysler Building (seen at left) is often held up as an example of Vitrolite. This is likely because Vitrolite tends to have better antique marketing cachet. The descriptions of PSG found in most of the images on this page refer to it as Vitrolite. Because Vitriolite and Carrara are nearly indistinguishable when looking at their top surface, it is easy to confuse them.

Vitriolite had a relatively short life. Its use declined in the 1950s as the style and tastes changed. Libbey-Owens-Ford shut its pigmented structural glass plant down in 1958 and Pittsburgh Plate Glass (then owner of Carrara) ended their production in the early 1960s. In the UK, production ceased in 1968 and around the end of the 20th century production ended in the facility in Bavaria, Germany. (Wikipedia) However, it found new life in the 21st century as a material for use in 3D printing. The Tethlon Bison ceramic DLP printer uses UV curing to create a part which "is a glass ceramic with high strength, low porosity/high density and thermal shock tolerance. It does not conduct heat or electricity and is chemical resistant. Vitrolite kiln fires at a relatively low temperature and results in a white glassy surface appearance." (Red Resins)

Other Online References:

Dusty Old Thing

High Style Deco

The West Virginia Encyclopedia Online

Vitriolite Specialist

Original Facebook Group Posting

Pigmented Structural Glass Examples, from left - Dark Blue ('Mahogany') and Princess Blue Wall Tiles, From Vitrolite Baths and Kitchens for All America, 1946, p. 8; Vitrolite, Bookends, Black and Green Vitrolite, Art Deco Collector; Frankl Glass, Streamline Moderne, Bookmatched Walnut Burl Veneer with Vitrolite Center, Black Lacquered Side and Legs, c. 1935, 1st Dibs

Pigmented Structural Glass Examples, from left - Dark Blue ('Mahogany') and Princess Blue Wall Tiles, From Vitrolite Baths and Kitchens for All America, 1946, p. 8; Vitrolite, Bookends, Black and Green Vitrolite, Art Deco Collector; Frankl Glass, Streamline Moderne, Bookmatched Walnut Burl Veneer with Vitrolite Center, Black Lacquered Side and Legs, c. 1935, 1st Dibs